Mandrel Comparisons

The #2MT-A mandrel fits all lathes with a #2 Morse taper. The 3/8" x 16 tpi stud has a flute in the threads making it self tapping. The thickest diameter is 7/8” and is preferred by turners who do not want to use it in their jaw chuck and are more comfortable with the thinner diameter. The spanner hole is used for leverage to help loosen turning; use 1/4" allen wrench or screw driver (photo). The back end is threaded 1/4" x 20 tpi for a draw bar.

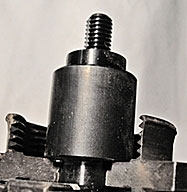

The #2MT-B mandrel fits all lathes with a #2 Morse taper. Because the body is thicker, 1 1/8” diameter, this mandrel has the additional option of being able to be used in a jaw chuck (see photo to right). A lot of turners do not want to remove the jaw chuck for each stopper. This mandrel has all the same features and costs the same as the #2MT-A and the spanner hole used same as above.

Draw bars hold the mandrels in securely and are 1/4-20 allthread (any hardware store) with a washer and handle to tighten it. You can also make your own as shown in the photo. Only the #2MT-A and #2MT-B can use a draw bar.

>

Mini and Midi lathes use a max. 10” length and full size lathes a max. 15” length. Be sure there is no more than 1" sticking out the back or it will whip and bend.

These mandrels are made to thread directly on the head stock spindle as shown on the right. You do not use a draw bar with these mandrels. There are flats on 2 sides of the neck for a wrench to hold the mandrel if the wood blank is hard to remove. This style mandrel is available in 3 sizes:

1” x 8 tpi = all Jet, Rikon and most midi and mini lathes

1.25” x 8 tpi = Robust, Laguna, Nova, Vicmarc,

Powermatic, etc.

M33x3.5m = A few models of Oneway full size lathes

This mandrel is for the ShopSmith lathes. It has a tapping flute in the threads to make it self-tapping and has a 5/8” opening for the headstock spindle and a set screw with the proper 3 degree angle.