1.25″x 8 Niles ™Mandrel

From: $19.50

$19.50 Fits spindle size 1 1/4″ x 8 tpi

$23.50 with 1 7/16″ stub drill bit for the stainless steel inserts

$26.98 with 2 stub drill bits: 5/16″ and 11/32″ $27.70 value

$30.98 with 5/16″ and 11/32″ stub drill bits and 3/8″ tap $32.95 value

Choose Options Below

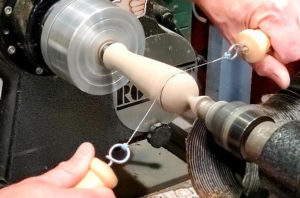

Niles ™mandrel threads onto the head stock spindle and has the unique tapered-cut flute making it the best self-tapping mandrel on the market. It has a 3/8″ x 16 tpi threaded stud that works with just about all the stoppers on the market and numerous other projects: ice cream scoop handles, shaving brushes, pizza cutters, etc. They have a black oxide coating for rust prevention. The neck or step below the threaded stud is 13/16″ diameter which matches the tops of all my stoppers. This mandrel does not use a draw bar. It comes with 2 nylon spacers (a spare because you will lose one!) which are used to help keep the wood from locking on the mandrel as you turn it. Use a 1 3/8″ wrench on the flats to start turning mandrel off the spindle.

If you are making the whiskey stoppers, SS-620 and/or SS-630, you might like the mandrel adapters that are the same diameter as these 2 stopper styles.

*Tip: if the wood does get a death grip and you can’t get the project off the mandrel, put the whole thing in the freezer for 10 – 15 minutes and it will unthread once the metal shrinks. Also try a little beeswax or soap on the mandrel before threading it into the wood.

The shorter stub drill bits won’t “wander” if they hit a tight wood grain. The 5/16″ is the standard size when threading a 3/8″ hole; the 11/32″ is for dense wood, acrylic and resins.

The bottoming tap cuts threads all the way in unlike regular taps that leave about 1/4″ untapped and it makes threading quick and easy.

Check this: Mandrel Comparison if you are not sure which mandrel to purchase: this page explains the differences and usages. If you are still not sure, please call me: 503-939-4565 and I will help you out.

This is a list of lathe spindle sizes and Morse taper if you are not sure: Lathe Specs

Basic bottle stopper turning video (threading the mandrel starts at about 3 min.): Roper Woodturning

Niles mandrels are only made in Missouri. If you have any questions, email Carl Jacobson at nilesstopper@gmail.com or call 503-939-4565, PST.

John McNary –

A well made piece. It seems to have been made with a good quality metal and good precision. I haven’t really taken advantage of the self tapping feature, as I’ve use brass inserts.

Tarn Faulkner –

Your #2MT-B Niles Mandrel seems okay, but doesn’t fit as accurately into my Robust lathe’s morse taper, so I don’t really use it unless I don’t have your other mandrel available.

Your 1.25”x8 Niles Mandrel works really well, seems very accurate, and is just the right size to still give me access to the workpiece

Tim Kennedy –

The mandrel I purchased recently has been great. I should have bought one of those earlier. It makes turning the bottle opener handles much, much easier.

Tom Bradley –

Great products the mandrel is the best one I have ever used holds the blanks steady and true while turning. I really like the heft of the hardware. It makes it feel sturdier. Great products all the way around.

Patrick Miller –

I like your products very much! The stoppers are very high quality. I’ll admit I’m still learning and trying to perfect the best way to thread the blank. I find hard to try and thread the blank (round or square) on to the mandrel. I’ve seen T-bar handle thread cutting tools. Perhaps you sell this and I don’t know. I should check your site. But overall I really love your products and will be ordering more!